As a master liftgate distributor, we often get asked by new liftgate owners, potential customers, and even our friends, some high level questions about liftgates and the industry as a whole. Today we’re going to explore some basic concepts of, what we do best, liftgates.

As always, if you have any questions, concerns, or would like more insight, please contact us, we’re here for you!

What you'll discover in this article:

- What is a liftgate?

- What components make up a liftgate?

- What are the benefits of a liftgate?

- What is the purpose of a liftgate’s cylinder?

- What is the purpose of a liftgate’s power unit?

- What is the purpose of a liftgate’s platform?

- What types of liftgates are there?

- Who manufacturers liftgates?

- How many liftgates are there in the United States?

- How is a liftgate installed?

What is a liftgate?

A liftgate is a mechanical device that is attached to the back or side of a truck or trailer and is used to raise and lower cargo from ground level to the bed of the truck or trailer. Liftgates are commonly found on delivery trucks, box trucks, and semi-trailers and are essential for loading and unloading heavy or bulky items that cannot be easily lifted by hand. They were created to reduce employee risk of injury, raise overall safety of the loading and unloading process, and increase productivity.

What components make up a liftgate?

Liftgates most commonly consist of several mechanical components, including a platform, cylinders, framing, and a power unit.

The platform is the horizontal surface that is used to support and transport cargo. The platform can be one, two, or three separate pieces depending on the style of gate you have.

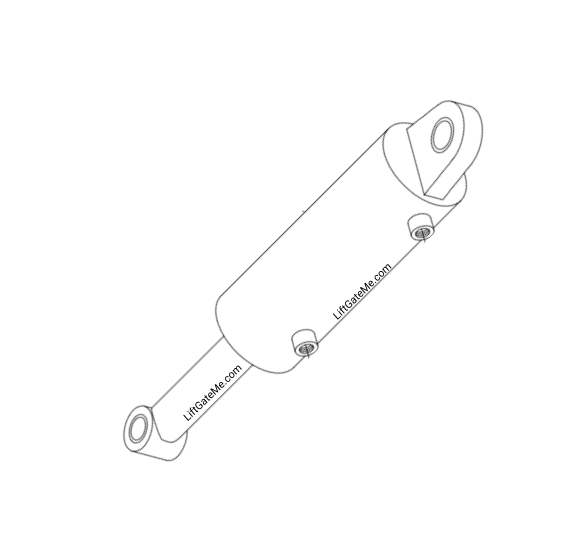

The cylinders are hydraulic components that are used to power the movement of the platform. Cylinders commonly found on a liftgate include a push/pull, tilt, open (aka a “fold” cylinder), and close cylinders.

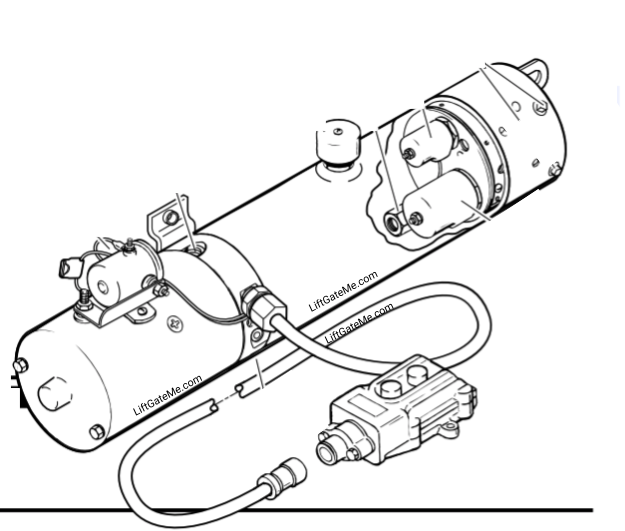

The power unit is a mechanical component that generates and provides the power needed to operate the liftgate. It will be complete with pump, motor, reservoir, solenoid, etc.

Although the majority of models have a single power unit, some liftgates have dual power units - a primary and a secondary. The secondary power unit is commonly only a motor and pump without a reservoir. It has the same function as the primary unit and attaches to the primary power unit through a valve block.

Have a question? We'd love to hear from you.

No liftgate serial number? Click here for a visual guide to locate it, then contact us.

What are the benefits of a liftgate?

There are several benefits to using a truck liftgate:

1. Increased safety: Liftgates allow workers to load and unload cargo without having to manually lift heavy items, which reduces the risk of injury.

2. Improved efficiency: Liftgates can significantly speed up the loading and unloading process, especially for large or heavy items. This can help reduce downtime and increase productivity.

3. Greater versatility: Liftgates can be used to load and unload a wide range of cargo, including pallets, drums, furniture, appliances, and more.

4. Enhanced convenience: Liftgates make it easier to load and unload cargo from a truck or trailer, especially for those who do not have the physical strength or capability to lift heavy items.

Overall, truck liftgates are an essential tool for businesses that rely on trucks and trailers to transport goods. They provide increased safety, improved efficiency, greater versatility, and enhanced convenience, making them a valuable investment for the majority of companies.

What is the purpose of a liftgate’s cylinder?

A cylinder on a liftgate is a hydraulic component that is used to power the movement of the liftgate. While many liftgates only have one cylinder, others, like slider gates, may have up to five cylinders.

A liftgate’s cylinder works by using pressurized fluid to extend and retract, which in turn moves the liftgate up and down, in and out, or open and close.

When the liftgate is activated, the cylinders extend, raising, opening or closing, tilting, pushing or pulling a platform in the direction selected. When the liftgate is deactivated, the cylinders are held in place.

The cylinder is an important part of the liftgate's mechanical system and plays a crucial role in the operation of the liftgate. Without the cylinder, the liftgate would not be able to function properly.

What is the purpose of a liftgate’s power unit?

A power unit on a liftgate is a mechanical component that is used to generate and provide the hydraulic pressure needed to operate the liftgate cylinders, actuating the whole gate. The power unit typically consists of an electric motor, a hydraulic pump, flow valve system, and a hydraulic reservoir for the fluid.

The electric motor is responsible for providing the drive or power to the hydraulic pump. When the liftgate is activated, the electric motor drives the pump, which pressurizes the hydraulic fluid and sends it to the liftgate's cylinders. The pressurized fluid then extends and contracts the cylinders, causing the liftgate platform to raise and lower.

The power unit is an essential part of the liftgate's mechanical system and is responsible for providing the power needed to operate the liftgate. Without a working power unit, the liftgate would not be able to function properly.

What is the purpose of a liftgate’s platform?

The platform on a liftgate is the horizontal surface that is used to support and lift cargo. It is most commonly located at the back of a truck or trailer and is raised and lowered by the liftgate's cylinders.

The platform is an essential part of the liftgate and serves several important functions:

1. It provides a stable surface for loading and unloading cargo.

2. It allows workers to easily access the bed of the truck or trailer to load and unload cargo.

3. It can be used to load and unload a wide range of cargo, including pallets, drums, furniture, appliances, and more.

A liftgate’s platform is an essential component of the liftgate and plays a crucial role in the loading and unloading process.

What types of liftgates are there?

There are several types of truck liftgates available on the market, each with their own unique features and benefits. Some common types of liftgates include:

1. Tuckaway gate: A tuckaway liftgate is a type of liftgate that can be tucked under the truck or trailer when not in use. Tuckaway gates are typically used on delivery trucks and are designed to be compact and easy to store.

2. Column Lift: One column on each side of the liftgate to raise and lower the platform.

3. Railgate: Similar to a Column Lift. A railgate is a type of liftgate that uses a left and right rail to support and guide the movement of the platform. Rail gates are often used on delivery trucks and are designed to be more lightweight than a column lift and easy to operate.

4. Cantilever liftgate: Commonly consists of a solid platform that will fold up against the back of the truck. These gates can also take the place of a rear door, sealing the rear of the cargo body from the elements through a set of seals.

5. Side loader: The platform is located on the side of the trailer/truck instead of the back hence the name side loader. Used for curbside deliveries where loading docks are not available.

6. Gas bottle liftgate: Commonly a repurposed rail gate or column lift model to safely help raise and lower cylinders on the platform. These gates normally have side support chains and arms to help prevent the bottled gasses from being able to fall off a platform while in motion.

Who manufacturers liftgates?

There are several companies that manufacture liftgates for trucks and trailers. Some of the leading manufacturers of liftgates include:

1. Maxon Lift: Maxon liftgate is a leading manufacturer for box trucks, pickup trucks, and trailers. They offer a variety of models, including railgates, tuckaway gates, cantilvers and more.

2. Hiab, who now owns Waltco Liftgate, is a another manufacturer of lift gates based out of Ohio. They offer a wide range of liftgate models, including railgates, tuckaway gates, and platform gates. They are also currently supporting Ultron Lift Corp. and Zepro.

3. Palfinger Liftgate has owned Interlift since 1993 and continues to produce high quality gates for trucks, vans, and other vehicles. They are known for high level engineering and reliable equipment.

4. Eagle Lift is a subsidiary of Palfinger but a separate entity unto themselves offer a smaller style gate for smaller vehicles.

5. Thieman Tailgates: Thieman Tailgates is a well-respected manufacturer of liftgates for trucks and trailers. They offer a variety of liftgate models, including telescoping gates, platform gates, and swing gates.

6. Anthony Liftgates: Anthony Liftgates is a well-known manufacturer of liftgates for trucks and trailers. They offer a range of liftgate models, including telescoping gates, platform gates, and swing gates.

7. Leyman Liftgates

8. Tommy Gate: Tommy Gate is a leading manufacturer of liftgates for trucks and trailers. They offer a wide range of liftgate models for various applications, including delivery trucks, box trucks, and semi-trailers.

How many liftgates are there in the United States?

It is difficult to determine the exact number of liftgates in the United States, as liftgates are commonly found on a variety of vehicles including delivery trucks, box trucks, and semi-trailers. In addition, liftgates are often used by businesses that operate fleets of vehicles, which makes it difficult to accurately estimate the total number of liftgates in the country.

According to Trucking.org, in 2020 there were 38.9 million trucks registered and used for business purposes and 4.06 million trucks, including tractors and straight trucks, in operation in 2021. Many of these trucks are equipped with liftgates, though it is not clear how many of them have liftgates installed.

It is also worth noting that liftgates are not just found on trucks and trailers. They are also commonly found on other types of vehicles, such as buses and vans, which further complicates the task of estimating the total number of liftgates in the United States.

How is a liftgate installed?

The process for installing a liftgate on a truck or trailer varies depending on the specific make and model of the liftgate. However, there are a few general steps that are typically involved in the installation process:

1. Preparation: Before installing the liftgate, the vehicle must be prepared. This typically involves removing any existing hardware or equipment that may interfere with the installation of the liftgate.

2. Mounting: The liftgate is then mounted to the back of the truck or trailer. This typically involves attaching brackets or other mounting hardware to the vehicle. Some liftgates are also directly welded to the vehicle or trailer.

3. Wiring: The liftgate's electrical system must then be wired into the vehicle's electrical system. This typically involves running wires from the liftgate's power unit to the vehicle's battery and/or other electrical charging components.

4. Hydraulics: The liftgate's hydraulic cylinder system must then be connected to the power unit of the gate.

5. Testing: After the liftgate is installed, it should be tested to ensure that it is functioning properly. This typically involves activating the liftgate and raising and lowering the platform to verify that it is working correctly.

Overall, the process for installing a liftgate on a truck or trailer is typically complex because it requires electrical, hydraulic, and welding work to be completed. Installation requires a skilled mechanic to ensure that it is done properly - luckily, our team can frequently assist in finding a reputable installer near you.

The liftgate industry is here to help

At LiftGateMe we’re proud of what we do. In 2021, there was 10.93 billion tons of freight transported by trucks, many of which have liftgates to assist in a more efficient means of delivery. Because of this, it’s clear that our liftgate industry will continue to play a vital role in the transportation of goods and we’re proud to be a part of it.

We have over 30 years of combined experience here at LiftGateMe and we are here to help!

If you have any other questions about liftgates or have suggestions, please reach out, we’re here for you!

Subscribe to keep in touch

Get our content delivered directly to your inbox. We're offering powerful content to keep you lifting throughout the year. Keep in touch with us to see why we're your Single Source partner for all things liftgate.